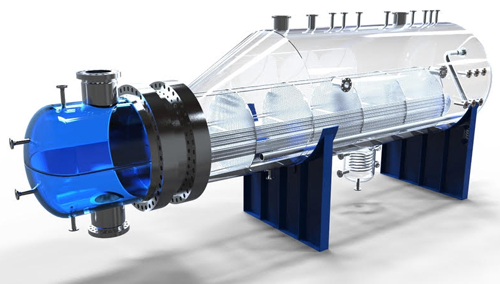

Kettle reboilers are reliable and effective heat exchangers often employed at the bottom of industrial distillation columns. They work by transferring heat from steam using a tube bundle, which evaporates some of the column bottoms liquid passing on the shell side. A retaining wall or an overflow weir maintains the tube bundle under liquid level so that it is possible to have uniform heat transfer and avoiding dry spots.

Such reboilers have high vaporization rates—80% or even higher, such that they are used in heavy-duty separation. In other systems, the liquid is fed to the reboiler by gravity, while some others need pumping from the column bottom. The vapor produced is recycled back into the distillation column to initiate the separation, while the residue liquid, also known as the bottoms product, is taken away.

Due to their simple, open-shell design, kettle reboilers are simple to operate, inspect, and maintain, and as such, are the first choice in most refining and chemical processing operations.