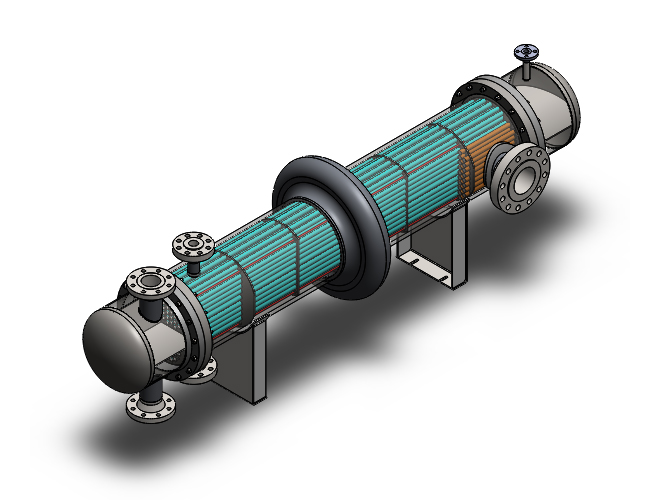

Shell and Tube Heat Exchangers have extensive applications in oil refineries, chemical plants, and industry owing to their ability, efficacy, and appropriateness for use in high- pressure conditions. They are a tube bundle placed in a cylindrical shell, facilitating heat transfer from one fluid flowing inside the tubes and another fluid flowing around the tubes.

There are two broad types: Fixed Tube Sheet, which is best for clean fluids and where mixing of the fluids should be avoided, and Floating Head,in which the tube bundle can be removed easily to carry out maintenance and cleaning.

These heat exchangers are applied in cooling hydraulic oils, engines, transmissions, and other industrial systems. With material choices such as stainless steel or copper, they are ideal for a variety of fluids, including corrosive or high-temperature media. Their modular configuration, ease of maintenance, and high thermal performance make them a dependable and versatile option for both heating and cooling applications.